Solutions for unmatched Asset Monitoring & CUI Management.

Optimize your asset monitoring and reduce the risk of CUI development with iSensPro’s Comprehensive Solution.

CONTENTS :

iSens-CUI Detection

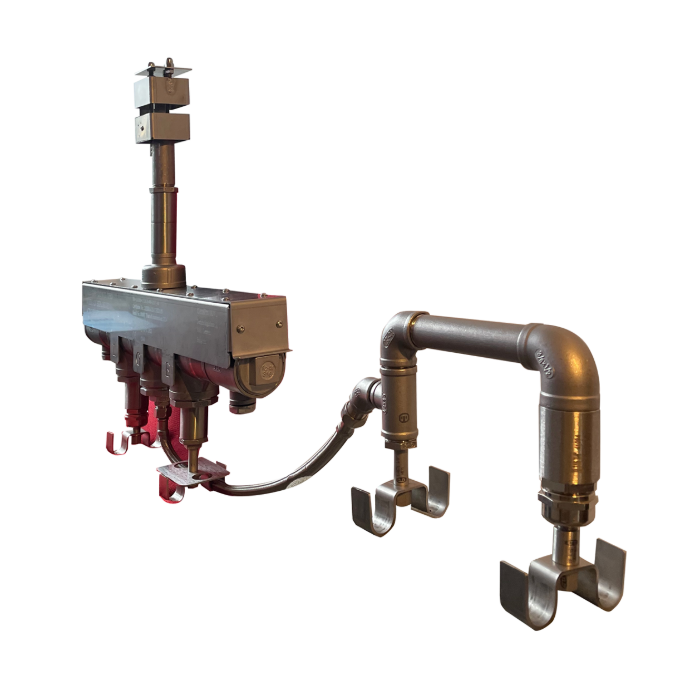

Our advanced sensor technology ensures real-time CUI detection for early risk identification supported by the Smart Gateway, which connects the data flow from sensor to decision-making.

Our fixed, patented ATEX and non-ATEX sensors deliver continuous monitoring for critical assets in both hazardous and non-hazardous environments.

The handheld device allows for quick, efficient inspections on the go.

ATEX Sensor

Single sensor measuring moisture & corrosion in/under insulation

Detects evolution in insulation and coating.

Non-intrusive, placed on top of the cladding

Capacitive measurement principle

Intrinsically safe ,ATEX Certificied II 1G ia IIC T4 Ga -40°C ≤ Ta ≤+55°C

Wireless Lora-communication

Battery powered ( > 10 years lifetime)

Data stored locally in gateway

Back to top

Non-Atex Sensor

Single sensor measuring moisture & corrosion in/under insulation

Detects evolution in insulation and coating.

Non-intrusive, placed on top of the cladding

Capacitive measurement principle

Wireless Lora-communication

Battery powered ( > 10 years lifetime)

Data stored locally in gateway

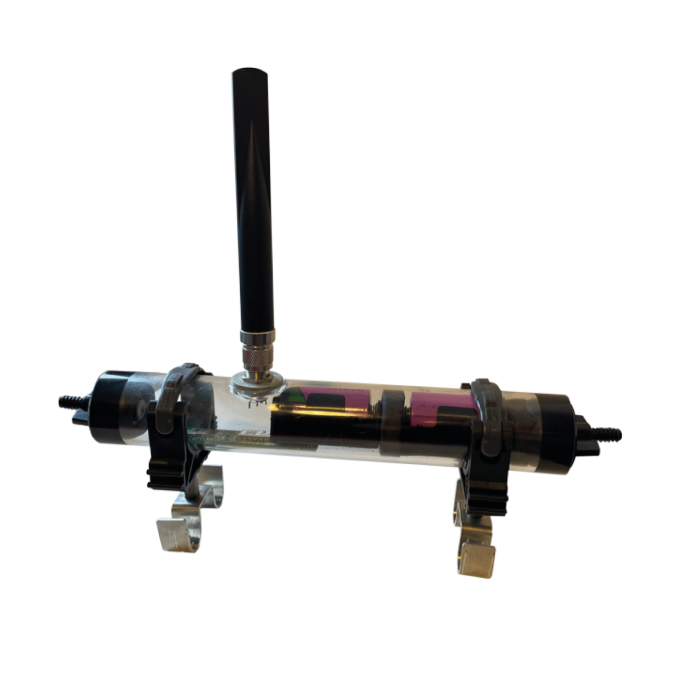

Handheld-Rugged Sensor

Mobile inspection Tool

Detects accurately moisture & CUI conditions in pipe segments

Indicates the actual conditions of insulation system

Stand-alone system with sensing,data storage, data analytics and visualization integrated in one unit.

Low weight & small dimensions

Battery powered & rechargeable

Wireless communications

Pluggable electrodes

Integration of Third party Sensors

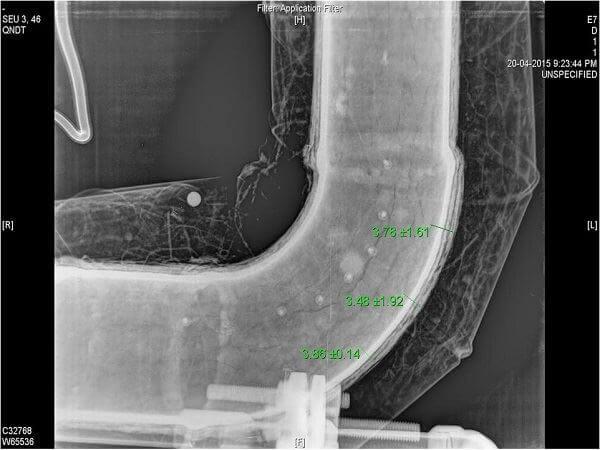

Seamlessly integrates with external tools to enable comprehensive CUI diagnostics

-

Radiography: Assesses pipeline wall thickness for internal corrosion insight

-

Infrared (IR) Thermography: Monitors surface temperature variations to identify anomalies

-

Pulsed Eddy Current (PEC) Testing: Detects corrosion and material loss through insulation

-

Enhances the overall reliability of inspection strategies by combining technologies

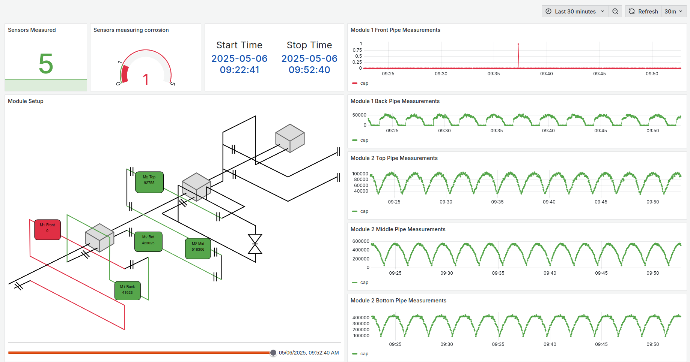

Dashboard

Presents real-time asset status in an intuitive visual format

Offers interactive charts and historical data trends for informed decisions

Enables customizable alerts and thresholds tailored to operational needs

Enhances visibility and control across multiple sites from a single interface

Designed for ease of use by engineers, operators, and managers alike

Smart Gateway

The smart gateway provides accessible insights through an intuitive GUI dashboard

Connects wirelessly (LORA) to 200 or more sensors for real-time data transmission

Securely stores sensor data locally on site , ensuring data integrity

Supports wired & wireless connections for seamless management systems.

Generates smart alarms for Immediate alerts of maintenance teams.

Benefits of iSens-CUI Detection: Innovative, Efficient, and Reliable

From seamless installation to real-time monitoring, iSensPro ensures operational efficiency and complete coverage.

Easy, non-intrusive installation

iSensPro's patented sensors work seamlessly on both new and existing equipment regardless of the asset's age:

- -No removal or replacement of insulation.

- Non-invasive, placed on top of the cladding.

- Wireless, hassle-free installation with no cabling headaches.Sensors send data wirelessly over LORA to the on-premise gateway.

Continuous Monitoring, 24/7

Data gathered continuously, provides a wealth of useful information to:

- Improve plant productivity

- Lower costs of inspection, labor and scaffolding.

- Reduce unplanned downtime

- Target maintenance actions better

360° Sensing

Data is collected from the entire circumference of the insulated pipe or tank, removing the human uncertainty factor inherent in installing sensors correctly.

Complete coverage eliminates human error:

- Enables 1 sensor to detect corrosion , coating degradation and moisture content across a whole segment (up to 1km)

iCollect - Asset Data

Automated data aggregation to organize and centralize critical asset information.

Once data is captured by our sensors, it is seamlessly organized within iCollect,the central hub for structured asset data. This system ensures that all CUI-related information is stored, searchable, and accessible for downstream analysis.

AI-Based Search Engine

Leverages a Large Language Model (LLM) to enhance the searchability and understanding of historical and real-time data.

AI-Based Search Engine

Leverages a Large Language Model (LLM) to enhance the searchability and understanding of historical and real-time data.

Dashboards Database

Securely stores CUI data for easy access and visualization.Actionable Recommendations

Suggest steps like inspection of cladding for moisture entry.

Benefits of iCollect: Intelligent, Centralized, and Actionable

From automated data capture to AI-powered search, iCollect transforms scattered sensor data into clear, accessible insights,supporting faster decisions and smarter asset management.

iLearn-Asset Learning

AI-driven analysis and insights for optimized asset operations and maintenance. When an anomaly is detected, our iLearn platform takes actions.

Workflow Database : Logs detected issues, recommended actions, and maintenance history.

Issue Verification: Confirm findings with handheld sensors for pinpoint accuracy.

Smart Feedback Loop: Log maintenance actions and costs for enhanced predictive accuracy.

Reinforcement Learning Engine: Uses machine learning algorithms to optimize inspection & maintenance processes over time.

Benefits of iLearn:Predictive, Evolving, and Insight-Driven

From smart alerts to AI-powered recommendations, iLearn transforms asset data into actionable maintenance strategies,helping teams stay ahead of failures, reduce costs, and optimize performance with confidence.

Intelligent Maintenance Planning

iLearn turns raw data into smart maintenance strategies that reduce cost, risk, and downtime:

- AI-driven recommendations on where and when to take action

- Issue verification using cross-referenced sensor and handheld data

- Optimized inspection cycles to avoid unnecessary checks

Increased Operational Efficiency

Proactive insights that prevent problems before they happen:

- Reduces unplanned downtime with early alerts

- Maximizes asset lifespan through timely intervention

Supports teams with clear, actionable guidance

Predictive Accuracy That Learns Over Time

With every data point, iLearn becomes more intelligent and precise:

- Machine learning engine improves forecasting from past behavior

- Adaptive planning adjusts strategies in real time

- Higher confidence in decisions with less uncertainty

iKnow: Asset Knowledge & Reporting

Effective

decision-making requires actionable insights.

iKnow

transforms

data into customized

reports

and

action plans that

align with the specific

needs of industrial operators.

Centralized Intelligence Hub: Consolidates data from iCollect and iLearn into one unified platform.

- Custom Reporting Engine: Generates tailored reports aligned with specific operational, compliance, and strategic goals.

- AI-supported Analysis: Interprets complex data patterns to support planning and decision-making.

- Dynamic Data Layer: Connects financial, operational, and maintenance data streams for holistic oversight.

- Collaborative Output Tools: Supports cross-functional access to actionable information across departments.

Strategic Integration: Links insights directly to procurement, resource allocation, and inspection planning.

Benefits of iKnow: Strategic, Informed, and Future-Ready

iKnow translates raw data and predictive insights into clear, actionable intelligence,empowering decision-makers with the tools they need to optimize costs, streamline operations, and plan for the future with confidence.

Strategic & Financial Clarity

- Financial Insights: Tracks costs and ROI for maintenance actions to improve profitability.

- Procurement Support: Informs smarter purchasing decisions based on real asset needs and usage.

Operational Performance

- Operational Reports: Evaluates efficiency and helps reduce downtime.

- Planning : AI-driven forecasting ensures timely inspections and proactive scheduling.

- Resource Allocation:Optimizes workforce and tool usage to reduce waste and boost productivity.

Safety & Sustainability

- Safety Metrics: Enhances visibility into asset risk, reducing human and environmental hazards.

- Sustainability Insights: Supports compliance and reduces carbon footprint through better asset use.

Frequently Asked Questions

iSensPro sensors are easy to install. They are non-intrusive and placed directly on top of the cladding, making the process quick and seamless. This design ensures minimal disruption, allowing them to be installed on both new and existing equipment with ease

With iSensPro’s real-time monitoring, inspections become streamlined. The sensors continuously gather data, so manual inspections are greatly reduced, saving time and resources.

iSensPro sensors use a capacitive measurement principle to detect changes in moisture levels and corrosion under insulation (CUI). By continuously monitoring the conditions on the asset's surface, they detect any moisture ingress or corrosion, providing early alerts so you can take action before serious damage occurs.

Yes, iSensPro sensors continuously collect 24/7 data and use advanced analytics to predict maintenance needs. By providing accurate assessments of asset lifespan and identifying the onset of deterioration, they enable proactive maintenance decisions based on real data rather than risk calculations, ensuring timely and effective interventions.

iSensPro sensors help asset managers mitigate risks by using real-time data to populate an RBI matrix, eliminating the need for calculated probabilities. This allows managers to anticipate and execute the appropriate level of maintenance, reducing costs associated with downtime, lost productivity, and potential facility shutdowns. Additionally, iSensPro frees up experts’ time, allowing them to focus on other critical maintenance issues.

Yes, iSensPro has case studies demonstrating cost savings and improved asset reliability. Please visit the Success Stories section of our website for detailed use cases and testimonials

iSensPro offers a complete infrastructure ranging from smart data sensors (iSens) to AI-powered analytics (iLearn), centralized data management (iCollect), and decision support tools (iKnow) designed to streamline asset monitoring and predictive maintenance from the field to the boardroom.

Our platform is built to be flexible and interoperable. The Smart Gateway and iKnow modules offer both wired and wireless connectivity, allowing seamless integration with your existing maintenance software, dashboards, or ERP systems.

Unlike manual, risk-based inspections, iSensPro provides 24/7 monitoring, AI-driven insights, and proactive maintenance planning,reducing unplanned downtime, inspection costs, and operational risk.

Through our iKnow module, we deliver tailored reports and insights for technical teams, maintenance planners, and executives,ensuring everyone has the right information to act quickly and effectively.

Yes, iSensPro’s modular and wireless design allows you to scale from a single pipeline to an entire facility or multiple sites, with centralized control and data visibility.